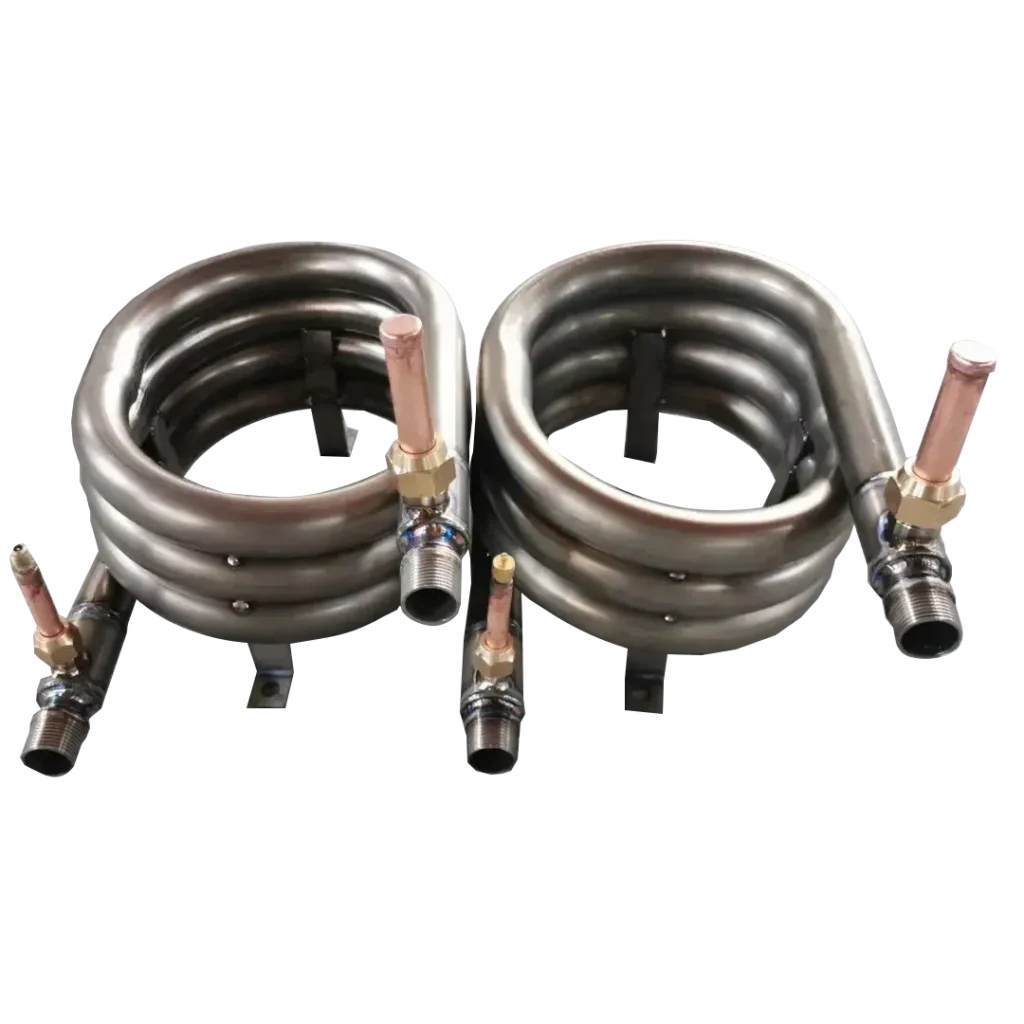

Tube In Tube Condenser

Coaxial Tube Heat Exchanger With Copper Inner Tube And Carbon Steel Outter Tube

Widely applicated on Heat Pump

- Water to Water or Air to Water Heat Transfer

- Waste Heat Recovery

- High Efficiency and Environmental Protection

Specification Data

Model | Outter Tube Diameter*Thickness*Length(mm) | Inner Tube Diameter*Thickness*Length(mm) | L*W*H(mm) | Refrigeration In/OutLet(mm) | Water In/Outlet(mm) |

3HP | φ35*2*4230 | φ32*0.8*4450 | 360*220*280 | φ12.7/16 | 1" |

5HP | φ38*2*5000 | φ32*0.8*5350 | 410*250*230 | φ12.7/19 | 1" |

6HP | φ38*2*6000 | φ32*0.8*6230 | 420*250*270 | φ12.7/19 | 1" |

7HP | φ42*2*6000 | φ38*0.8*6230 | 420*250*300 | φ12.7/19 | 1" |

10HP | φ38*2*(5000*2) | φ32*0.8*(5230*2) | 500*250*520 | φ12.7/19 | 1.5" |

Describtion

Coaxial heat exchanger can enlarge the heat transfer area by changing the length of inner spiral tube. Water and refrigerant flow around the inner spiral tube in reverse direction. After refrigerant cooling and liquefaction condensation, the surface tension of liquid film in the tube reduces the heat transfer resistance and improves the heat transfer efficiency.

Coaxial heat exchanger consist of one spiral grooves inner tube and a outer tube. Cold liquid and heat liquid flow in the gap that between inner and outer tube or in inner tube separately.

Structure Feature

High efficiency

Spiral groove structure can enhance heat transfer on both sides. The axial flow and spiral rotation flow of the fluid in the tube will intensify the mixing of the fluid near the tube wall, thus enhancing the turbulence intensity and increasing the heat transfer coefficient

Self-cleaning ability

The coaxial heat exchanger has self-cleaning ability because the fluid spiral flow washes the surface. Coaxial heat exchanger has stable performance and low attenuation. The cross-section area of the waterway is large, allowing sediment and large diameter fibers to pass through without blocking. The water passage is clean because the inner tube of the spiral groove keeps the flow turbulent and cleans the surface

Effective prevention of freezing

Water is not easy to freeze because it is turbulent when it flows at a low speed in a spiral groove. The special spiral groove structure of the inner tube makes the inner tube flexible to a certain extent and does not produce the risk of frost cracking.

Less risk of leakage

Heat exchangers are very worried about leakage due to long-term vibration, pressure fluctuation, alternation of heat and cold, and so on. The risk of leakage of coaxial exchangers is seldom due to fewer welding points, simple processing and easy control of welding quality

Adapt to all kinds working conditions

In the actual operation of refrigeration system, the internal pressure is often in an alternate state due to temperature fluctuation, start-stop cycle, heat pump defrosting, expansion valve regulation and other factors. Spiral coaxial heat exchanger is more resistant to pressure shock and pressure shock than plate heat exchanger under constant vibration and pressure change, and can adapt to the complexity of actual working conditions

Kinds of coaxial heat exchanger that APT design and produce

- Based on shape Circle ,Rectangle,Double helix,Spiral,Trombone

- Based on system No. Single system,Double helix type 3 systems,Trombone interspersed 2 systems,Trombone type 6 systems,Spiral type 9 systems

- Based on material Red copper,Cupronickel (BFe-10-1-1),Titanium,Stainless steel,Steel

Coaxial tube heat exchanger inner tube material:

Coaxial heat exchanger inner tube is composed of pure copper, double-layer copper, nickel white copper, titanium tube, high quality copper, stainless steel and other materials. The inner tube thickness is 0.8mm. Four, six and eight heads can be customized according to customer’s requirements, and the material can be baked paint anti-corrosion treatment.

Coaxial tube heat exchanger outer tube material:

Coaxial tube heat exchanger inner tube can be made of different materials such as high quality copper, 316L, 304 stainless steel, nickel copper, titanium tube and so on.