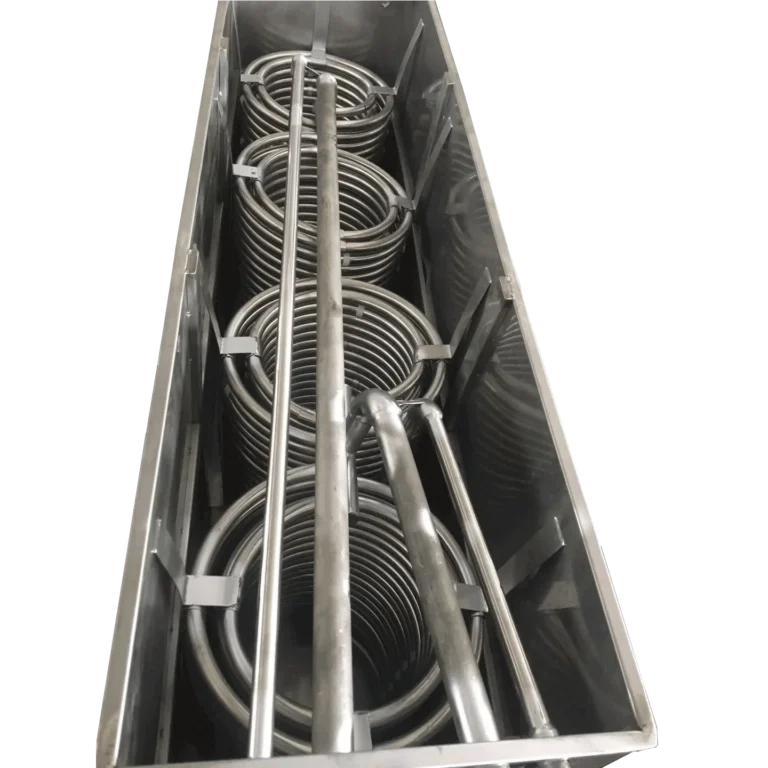

Industry used heat exchanger

Stainless Steel 304 Coil Tube with Water tank heat exchanger

Widely applicated on Laser Cutting/Plastic Injection/Electroplating Chemical ndustry,etc…

- Immersion tube,Air to Water Heat Transfer

- High Efficiency

- Convenient for daily management and maintenance

Specification Data

Power(HP) | Tube Diameter(mm) | Tube Length(mm) | Tank Length(mm) | Tank Width(mm) | Tank Height(mm) |

5HP | φ19*0.7mm | 25000 | 350 | 350 | 450 |

8HP | φ19*0.7mm | 2*20000 | 800 | 350 | 510 |

10HP | φ19*0.7mm | 2*25000 | 850 | 380 | 530 |

15HP | φ19*0.7mm | 3*25000 | 1150 | 380 | 530 |

20HP | φ19*0.7mm | 4*25000 | 1200 | 440 | 640 |

25HP | φ19*0.7mm | 5*250000 | 1400 | 450 | 550 |

30HP | φ19*0.7mm | 6*25000 | 1400 | 520 | 650 |

Describtion

Advantages of APT stainless steel heat exchange products

- Choose the appropriate stainless steel model according to the customer’s working conditions, give full play to its maximum corrosion resistance and ensure the heat transfer effect.

- Professional and standardized welding process to ensure that the weld is not leakage, the starting point and source of corrosion.

- Factory price and professional engineering services.

Application case

Stainless steel coil ss304 water tank heat exchanger is widely used for freezing industries, such as plating, oxidation, chemical industry, metallurgy, light industry, shipbuilding, heating, pharmaceutical, foodstuff ect, also for leather chiller, injetion molding machine chiller, print chiller, PV shoe machine chiller and so on.

Structure Feature

- The stainless steel tube has the advantages of good heat resistance, excellent machinability, good thermal conductivity, high heat transfer efficiency, non-toxic, non-magnetic, non-polluting medium, non-scaling and strong pressure-bearing capacity. The heat exchanger tube is inspected with 3.0Mpa nitrogen to ensure cold. The medium system is safe and airtight.

- The shell water tank is formed by high quality PP injection moulding, which improves the product quality, improves the appearance and reduces the labor cost.

- Design pressure of evaporator refrigerant system: 3.0Mpa is suitable for refrigerants such as R22, R407C, R410A and R134a.

- The design temperature of the evaporator water system is – 10 C – 80 C.

- Application:Beer cooling, Laser water cooler, UV-LED lamp water cooler, water cooler and other fields