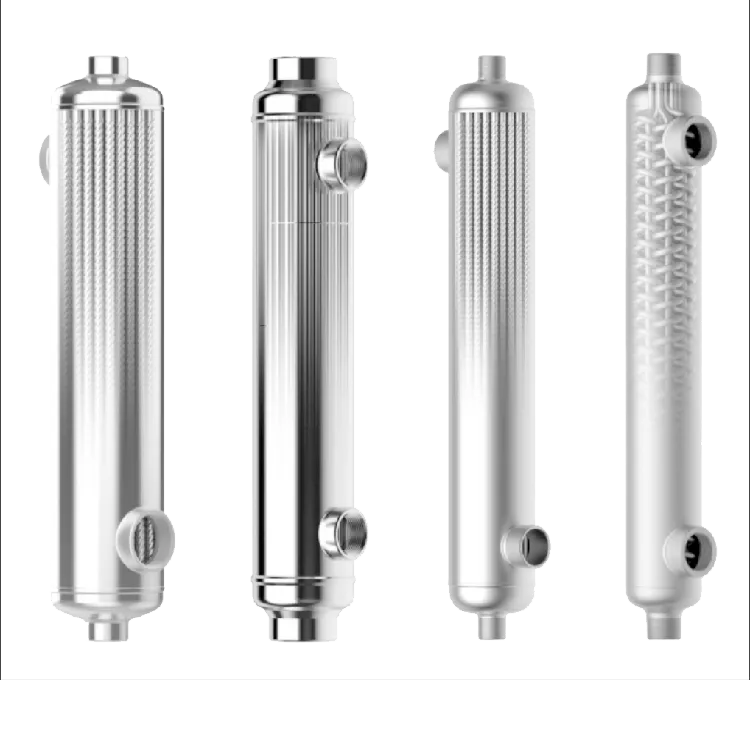

Compact Tubular heat exchanger

Stainless Steel 304 Heat Exchanger for Swimming pool water heater

Widely applicated on swimming pool boiler

- Water to Water or Air to Water Heat Transfer

- Waste Heat Recovery

- High Efficiency and Environmental Protection

Specification Data

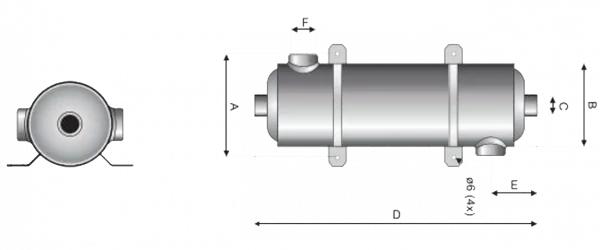

Model No. | Cooling /Heating capacity

(KW) | Hot Water Flow Rate (L/min) | Cool Water Flow Rate

(L/min) | Pool Volumn

(M³) | A (mm) | B (mm) | C (inch) | D (mm) | E (mm) | F (inch) |

MF-80 | 24 | 20 | 150 | <30 | 139 | 133 | 1" | 300 | 92 | 1.5" |

MF-135 | 40 | 25 | 200 | 30-60 | 139 | 133 | 1" | 355 | 92 | 1.5" |

MF-200 | 60 | 30 | 250 | 60-75 | 139 | 133 | 1" | 485 | 92 | 1.5" |

MF-260 | 75 | 35 | 300 | 75-115 | 139 | 133 | 1.5" | 613 | 92 | 1.5" |

MF-400 | 120 | 50 | 360 | 115-175 | 139 | 133 | 1.5" | 1070 | 83 | 1.5" |

MF-800 | 200 | 100 | 500 | / | 139 | 133 | 1.5" | 1740 | 83 | 1.5" |

Describtion

Tubes in shell heat exchanger can enlarge the heat transfer area by changing the length of inner spiral tube. Water and refrigerant flow around the inner spiral tube in reverse direction. After refrigerant cooling and liquefaction condensation, the surface tension of liquid film in the tube reduces the heat transfer resistance and improves the heat transfer efficiency.

Wate to water/ air to water heat exhcanger with high heat transferring efficient heat exchanger tubes and smooth shell, it ensures high velocities inside of the unit making the heat exchanger a very reliable, efficient and cost effective way to transfer heat indirectly between any boiler/solar water heater or heat pump water heater circuit and any pool or spa circuit, besides other applications.

Structure Feature

High efficiency

Spiral groove structure can enhance heat transfer on both sides. The axial flow and spiral rotation flow of the fluid in the tube will intensify the mixing of the fluid near the tube wall, thus enhancing the turbulence intensity and increasing the heat transfer coefficient

Self-cleaning ability

Self-cleaning ability because the fluid spiral flow washes the surface. this heat exchanger has stable performance and low attenuation. The cross-section area of the waterway is large, allowing sediment and large diameter fibers to pass through without blocking. The water passage is clean because the inner tube of the spiral groove keeps the flow turbulent and cleans the surface

Effective prevention of freezing

Water is not easy to freeze because it is turbulent when it flows at a low speed in a spiral groove. The special spiral groove structure of the inner tube makes the inner tube flexible to a certain extent and does not produce the risk of frost cracking.

Less risk of leakage

Heat exchangers are very worried about leakage due to long-term vibration, pressure fluctuation, alternation of heat and cold, and so on. The risk of leakage of coaxial exchangers is seldom due to fewer welding points, simple processing and easy control of welding quality

Adapt to all kinds working conditions

In the actual operation of refrigeration system, the internal pressure is often in an alternate state due to temperature fluctuation, start-stop cycle, heat pump defrosting, expansion valve regulation and other factors. Spiral coaxial heat exchanger is more resistant to pressure shock and pressure shock than plate heat exchanger under constant vibration and pressure change, and can adapt to the complexity of actual working conditions